Views: 0 Author: Site Editor Publish Time: 2026-01-07 Origin: Site

Industrial processes depend on heat, but not all heat is created equally. Behind every boiler, furnace, or production line is an industrial burner doing the real work. In this guide, you’ll learn what an industrial burner is, how it works, and why efficiency and emissions matter. We’ll also explore key burner types, applications, and selection insights for engineers and decision-makers.

Table of Contents

What Is an Industrial Burner?

How Industrial Burners Work?

Main Types of Industrial Burners

Key Components of an Industrial Burner

Industrial Burner Applications and Use Cases

Industrial Burners and the Future of Sustainable Combustion

Frequently Asked Questions (FAQ)

Conclusion: Choosing the Right Industrial Burner for Long-Term Performance

An industrial burner is a combustion device designed to produce controlled heat for industrial systems. It burns fuel safely and delivers thermal energy where processes need it most. Unlike residential or commercial burners, industrial burners handle higher power, larger volumes, and tougher conditions. They operate continuously, often under precise control and strict safety requirements. At its core, an industrial burner converts fuel into controlled thermal energy.

It manages fuel flow, air supply, ignition, and flame stability as one system.

| Burner Type | Typical Capacity | Control Level | Use Environment |

|---|---|---|---|

| Residential | Low | Basic on/off | Homes |

| Commercial | Medium | Limited modulation | Buildings |

| Industrial | High to very high | Advanced modulation | Factories, plants |

An industrial burner supplies heat to boilers, furnaces, ovens, kilns, and process heating systems. It supports steam generation, material heating, drying, melting, and thermal treatment. In boilers, it generates steam or hot water for energy and production. In furnaces and kilns, it delivers intense, stable heat for material transformation.

Combustion quality directly affects system performance. Efficient combustion improves fuel use, lowers emissions, and protects downstream equipment. Poor combustion wastes energy and stresses the system. Good combustion keeps temperatures stable, flames controlled, and operations reliable.

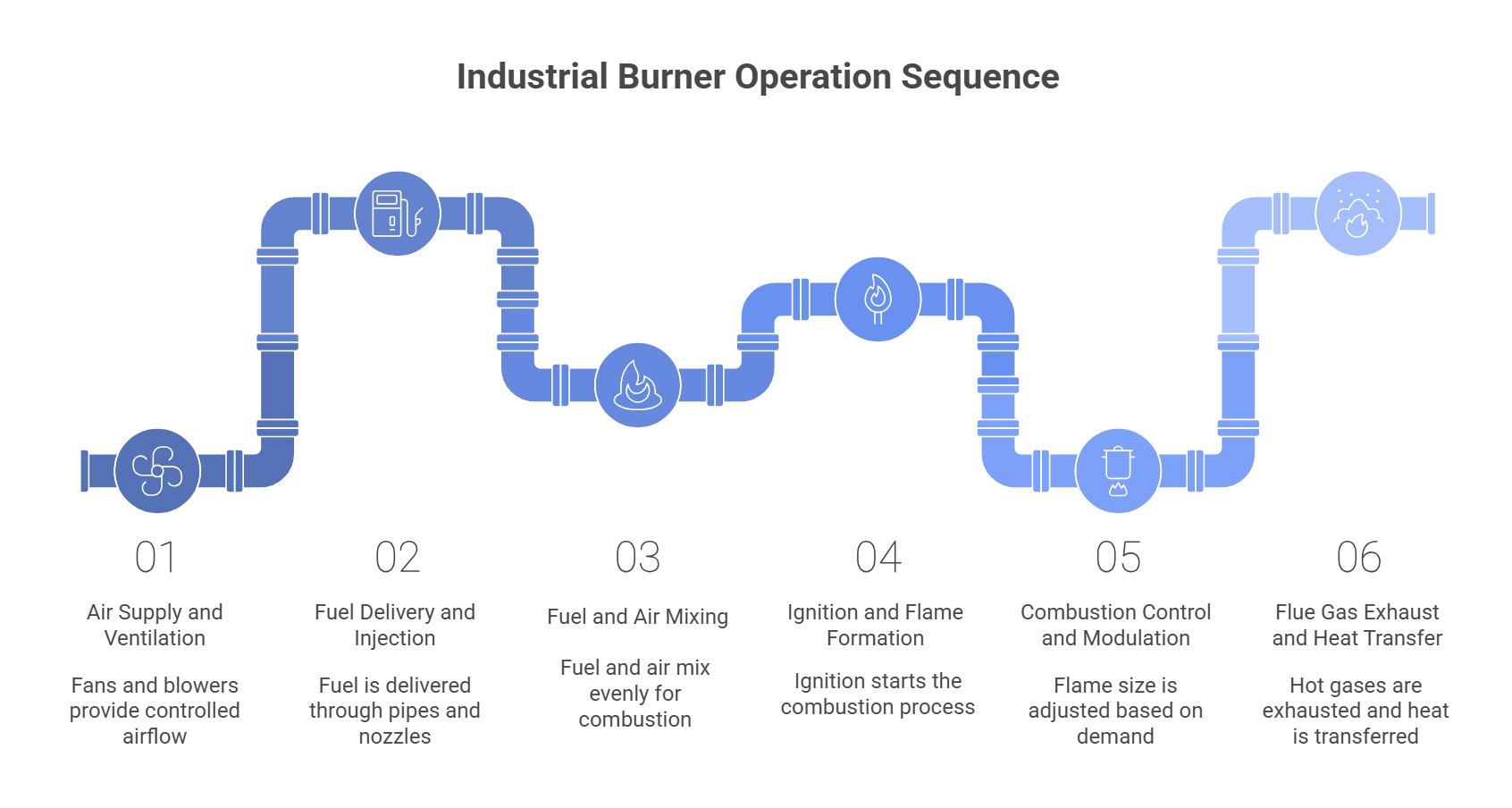

Every industrial burner follows a simple rule. Fuel + air + ignition = a controlled flame. They manage these three elements carefully. We control timing, pressure, and flow to keep combustion stable. When balance stays right, heat stays useful. When balance breaks, efficiency and safety suffer.

Burners need oxygen to work. Fans and blowers push air into the system. They move air at controlled speeds. Too little air causes incomplete combustion. Too much air wastes heat. The air-to-fuel ratio keeps everything balanced.

Fuel enters after airflow stabilizes. Gas flows through pipes and valves. Liquid fuel moves through pumps and nozzles. Pressure regulators keep delivery steady.

| Fuel Type | Delivery Method | Key Control |

|---|---|---|

| Gas | Valves and manifolds | Pressure regulation |

| Liquid | Pumps and nozzles | Flow and atomization |

Fuel and air must mix evenly. Gas mixes directly inside the burner head. Liquid fuel gets atomized into fine droplets. Better mixing means cleaner combustion. It improves efficiency. It also lowers unwanted emissions.

Ignition starts the process. Large burners often use pilot flames. Smaller burners rely on ignition electrodes. They spark directly inside the chamber. Systems follow a safe ignition order. Fuel enters only after ignition confirms readiness.

Some burners run on simple on/off control. They switch fully on or fully off. Others use modulating control. They adjust flame size as demand changes. This keeps temperatures steady. It also reduces fuel waste during partial loads.

Combustion creates hot gases. They move through the system after releasing heat. Chimneys or stacks guide them out. Heat exchangers capture useful energy first. Clean exhaust flow protects equipment. It also keeps pressure stable inside the burner system.

Gas burners run mainly on natural gas. They deliver steady heat and respond quickly to load changes.

They burn clean and efficiently. Emissions stay low when air and fuel stay balanced. Common applications include boilers, ovens, and dryers. Food processing, chemicals, and power plants use them widely.

Why many plants choose gas burners

High combustion efficiency

Lower NOx and CO emissions

Simple fuel handling and control

Oil burners typically use light fuel oil or diesel. They suit locations where gas supply stays limited or unstable. They produce strong, reliable flames. Maintenance needs stay higher than gas systems. Emissions rise without proper tuning. Regular nozzle cleaning and fuel filtering help.

| Aspect | Oil Burners |

|---|---|

| Fuel type | Light oil / diesel |

| Emissions | Higher than gas |

| Maintenance | More frequent |

Heavy oil burners use heavy fuel oil, often called mazut. It carries high energy but flows slowly at room temperature. Fuel needs preheating before injection. Pipes, tanks, and pumps require insulation and heaters. They support very high heat output. Cement plants and refineries rely on them. Trade-offs exist. Emissions increase, and systems grow more complex.

Dual-fuel burners operate on gas and oil. They switch fuels automatically when supply changes. Multi-fuel burners accept several fuel types. They offer flexibility during price swings or outages. Power plants value redundancy. Refineries use them for uninterrupted operation.

Key advantages

Fuel flexibility

Backup during fuel shortages

Reduced downtime during transitions

Monoblock burners combine the fan and burner body into one unit. They install faster and save space. Duoblock burners separate the fan from the burner. They handle higher capacities and allow flexible airflow control. Installation differs. Monoblock suits compact systems. Duoblock fits large boilers and furnaces.

| Feature | Monoblock | Duoblock |

|---|---|---|

| Structure | Integrated | Separate fan |

| Capacity | Low to medium | Medium to very high |

| Maintenance | Simple | More adjustable |

Premix burners blend fuel and air before ignition. They deliver uniform flames and low emissions. Nozzle-mix burners keep fuel and air separate until ignition. They improve safety and resist flashback. Emission behavior changes by design. Premix often lowers NOx. Nozzle-mix offers stable control in harsh conditions.

Key differences

Premix: cleaner burn, tighter control

Nozzle-mix: safer operation, wider fuel tolerance

Direct-fired burners release heat straight into the process air. Efficiency stays very high. Indirect-fired burners transfer heat through a heat exchanger. Process air stays clean. Choose indirect systems when contamination matters. Food, pharma, and coatings depend on isolation.

| System Type | Heat Path | Typical Use |

|---|---|---|

| Direct-fired | Flame to air | Drying, ventilation |

| Indirect-fired | Through exchanger | Clean processes |

High-velocity burners push heat deep into chambers. They improve mixing and temperature uniformity. Duct burners mount inside air ducts. They heat moving air directly. Process burners serve specific industrial tasks. They keep flames stable under changing loads. They work well in dryers, ovens, and furnaces. Temperature stays even across the system.

Industrial burners rely on several coordinated systems. Each component plays a role in safe, stable, and efficient combustion. Together, they control how fuel and air enter, ignite, burn, and shut down.

The fuel train manages how fuel reaches the burner. It controls pressure, flow, and safety before combustion begins. Valves open and close fuel paths. Regulators keep pressure within limits. Filters remove impurities before they cause damage. Gas fuel trains stay relatively simple. Liquid fuel systems add pumps, heaters, and finer filtration.

| Fuel Type | Core Elements | System Complexity |

|---|---|---|

| Gas | Valves, regulators, switches | Medium |

| Liquid | Pumps, filters, heaters | Higher |

Once fuel arrives, the combustion head takes over. It shapes the flame and guides fuel into the airflow. Gas nozzles release fuel evenly. They help create stable, well-distributed flames.

Liquid fuel nozzles atomize oil. They turn fuel into fine droplets for cleaner burning.

Air makes combustion possible. Fans or blowers push air into the burner. Dampers adjust airflow precisely. They help keep the air-to-fuel ratio stable. In monoblock burners, the fan mounts directly on the burner. Remote fan systems use ducts for larger or flexible layouts.

Ignition starts the combustion process. It must work only at the right moment. Large burners often use pilot flames. Smaller units rely on ignition electrodes and transformers. The sequence stays strict. Air flows first, ignition follows, fuel enters last.

The electrical panel connects everything. It supplies power and coordinates signals. Motor starters run fans and pumps. Fuses and breakers protect circuits from faults. Wiring links sensors, controls, and safety devices. They all respond together.

The control system manages burner behavior. It reacts to load changes and operating conditions. Controllers use analog or digital logic. They adjust fuel and air automatically. Sensors track temperature, pressure, and flue gases. Actuators and valves respond in real time.

Safety systems guard every operation. They monitor conditions continuously. Flame detectors watch for flame loss. Safety shut-off valves stop fuel instantly. Pressure switches check limits. Emergency shutdowns and alarms protect people and equipment.

Industrial burners appear across many industries. They deliver reliable heat wherever processes demand control, scale, and safety.

Boilers rely on burners as their heat source. They generate steam, hot water, or thermal oil.

Steam supports power, cleaning, and production. Hot water serves heating systems. Thermal oil handles high temperatures at low pressure. Burners must stay stable under changing loads. Efficiency directly affects fuel cost and uptime.

Process heating demands precision. Burners raise materials to exact temperatures. Furnaces use them for melting, forming, and heat treatment. They keep temperature uniform across chambers.

Small changes matter. Good flame control protects product quality.

Asphalt plants need intense, consistent heat. Burners dry aggregates and heat bitumen.

Fuel flexibility matters here. Many plants use oil, gas, or dual-fuel burners. Stable flames keep mix quality steady. Downtime quickly affects production schedules.

Food processes depend on controlled heat. Burners support baking, roasting, and drying.

Clean combustion stays critical. Indirect-fired systems often protect food from contamination. Temperature uniformity matters. It affects taste, texture, and safety.

These industries demand extreme heat. Burners reach very high temperatures reliably. They support melting, firing, and sintering. Flame stability protects product consistency. Emissions control matters here. Many facilities adopt low NOx designs.

Power plants rely on burners for startup and backup heat. They ignite boilers and support steady operation. Fuel availability changes often. Dual-fuel systems improve reliability. Efficiency links directly to output. Emission limits shape burner selection decisions.

Industrial combustion keeps changing. Efficiency alone no longer drives decisions. Environmental pressure, digital tools, and operating costs now shape burner design.

Emission rules grow stricter every year. Many facilities must cut NOx without losing performance. Low NOx burners lower flame temperature. They limit nitrogen oxide formation during combustion. Ultra-low NOx systems go further. They use staged combustion, advanced burner heads, or flue gas recirculation.

| Burner Type | Typical NOx Level | Common Use |

|---|---|---|

| Conventional | Higher | Legacy systems |

| Low NOx | Reduced | Industrial boilers |

| Ultra-Low NOx | Very low | Regulated regions |

Burners now think digitally. Controllers adjust fuel and air in real time. Sensors feed data continuously. They track temperature, pressure, and exhaust gases. Smart systems connect to plant networks. Operators monitor performance remotely. They catch issues early. Maintenance becomes planned, not reactive.

Sustainability involves trade-offs. Cleaner combustion often adds complexity. Efficient burners reduce fuel use. Low emissions help meet regulations. Smart control lowers long-term costs. Initial investment rises, operating cost drops. Plants now look at the full picture. They choose burners balancing performance, compliance, and lifetime expense.

A: It generates controlled heat for boilers, furnaces, ovens, kilns, and many industrial process heating systems.

A: Main types include gas burners, oil burners, heavy oil burners, and dual-fuel or multi-fuel burners.

A: It supplies air, injects fuel, ignites the mixture, and controls the flame to produce stable heat.

A: Natural gas burners, especially low NOx and ultra-low NOx designs, produce the lowest emissions.

A: Boiler burners serve boilers specifically, while industrial burners cover many heating and process applications.

A: Monoblock burners integrate the fan; duoblock burners use a separate fan for higher capacities.

A: They lower flame temperature using staged combustion and precise air-fuel ratio control.

A: Regular inspections plus annual servicing are recommended, more often under heavy or continuous operation.

In this guide, we explored what industrial burners are, how they work, and where they are used. We covered fuel types, design configurations, core components, and real-world applications across major industries. We also looked ahead at low NOx technologies, smart controls, and the push toward cleaner, more efficient combustion.

If you are currently looking for an industrial boiler solution, EBICO is a trusted choice.

As an industry-leading industrial boiler manufacturer, EBICO has designed and manufactured industrial boilers since 1965. Our systems focus on efficiency, reliability, and compliance with modern emission standards. Explore our industrial boiler products and contact us today to discuss your project needs and technical requirements.