Views: 0 Author: Site Editor Publish Time: 2026-01-05 Origin: Site

Stricter emission rules are reshaping industrial combustion. Plants must cut NOx without losing performance. If you run a boiler or asphalt mixing plant, this matters. Sustainability and compliance now affect purchasing decisions.

So what is a low NOx burner in real operations? How do low nitrogen oxide burners actually reduce emissions? In this article, you’ll learn how a low nox burner works. And how to choose the right solution for your application.

Table of Contents

What Is NOx and Why Must It Be Reduced in Combustion Systems?

What Is a Low NOx Burner?

How Does a Low NOx Burner Work?

Where Are Low NOx Burners Commonly Used?

Conclusion

Where can I find Low-NOx Burner manufacturers?

FAQ

NOx is a scientific umbrella term. It mainly means nitric oxide (NO) and nitrogen dioxide (NO₂). They are reactive gases, made from nitrogen and oxygen. In many combustion sources, NO is the bigger share. Later, NO can turn into NO₂ in air chemistry.

NO₂ can irritate airways and worsen asthma symptoms.

NOx also helps form ground-level ozone, a smog driver.

It also contributes to acid rain chemistry in the atmosphere.

| Term | What it is | Why you’ll see it in specs |

|---|---|---|

| NO | Nitric oxide | Often dominates at the stack right after combustion |

| NO₂ | Nitrogen dioxide | Key health concern, used in many air rules |

| NOx | NO + NO₂ (mostly) | The compliance number for permits and guarantees |

You’ll see it in boilers, heaters, furnaces, kilns, and ovens. People may not notice it, but monitors do. We track it because limits affect permits and uptime.

Here are the NOx “types” buyers often hear about:

| NOx type | Main driver | Why it matters for buyers |

|---|---|---|

| Thermal NOx | High flame temperature, oxygen present | Often the biggest target in gas and oil systems |

| Fuel NOx | Nitrogen inside the fuel | More relevant for some fuels, less for natural gas |

| Prompt NOx | Early flame reactions near the burner zone | Usually smaller, still part of total NOx |

NOx rises when flames hit very hot peaks. It also rises when oxygen reaches those hottest zones. So it’s a temperature problem and an oxygen problem. It can grow if gases stay hot for longer.

A simple mental model helps during burner selection:

Hotter core → faster NOx formation.

More O₂ near the core → more NOx pathways.

Longer high-heat time → higher final NOx.

NOx links to smog and ground-level ozone. It can worsen asthma and other breathing issues. It also contributes to acid rain and ecosystem damage. Rules keep tightening, especially near urban airsheds. Buyers often face these practical pressures:

Permit limits tied to location and equipment size.

Emissions tests during commissioning and audits.

Sustainability targets from owners, clients, investors.

Cost risk from fines, downtime, forced retrofits.

After understanding what NOx is, the next question becomes practical. What solution actually reduces it at the source?-low NOx Burner. A low NOx burner is a burner designed to reduce nitrogen oxide formation by controlling how fuel and air mix and burn, lowering peak flame temperature and limiting oxygen in the hottest zones during combustion. So the definition goes beyond emissions numbers. It describes how combustion is shaped and managed. Temperature peaks stay lower. Oxygen stays away from the hottest flame zones. That is why “low NOx” is a design approach. Not just a label on a datasheet.

In real plants, problems are rarely theoretical. Operators face permits, inspections, and downtime risks. A low NOx burner helps solve issues like these:

Emission limits during startup and full load

Stable flame across wide turndown ranges

Compliance in boilers, furnaces, asphalt plants

Long-term sustainability targets from owners

They also deal with trade-offs. Lower NOx can increase CO if poorly tuned. Heat demand cannot drop just to meet limits. Low NOx burners exist to balance all three: emissions, efficiency, and operational stability.

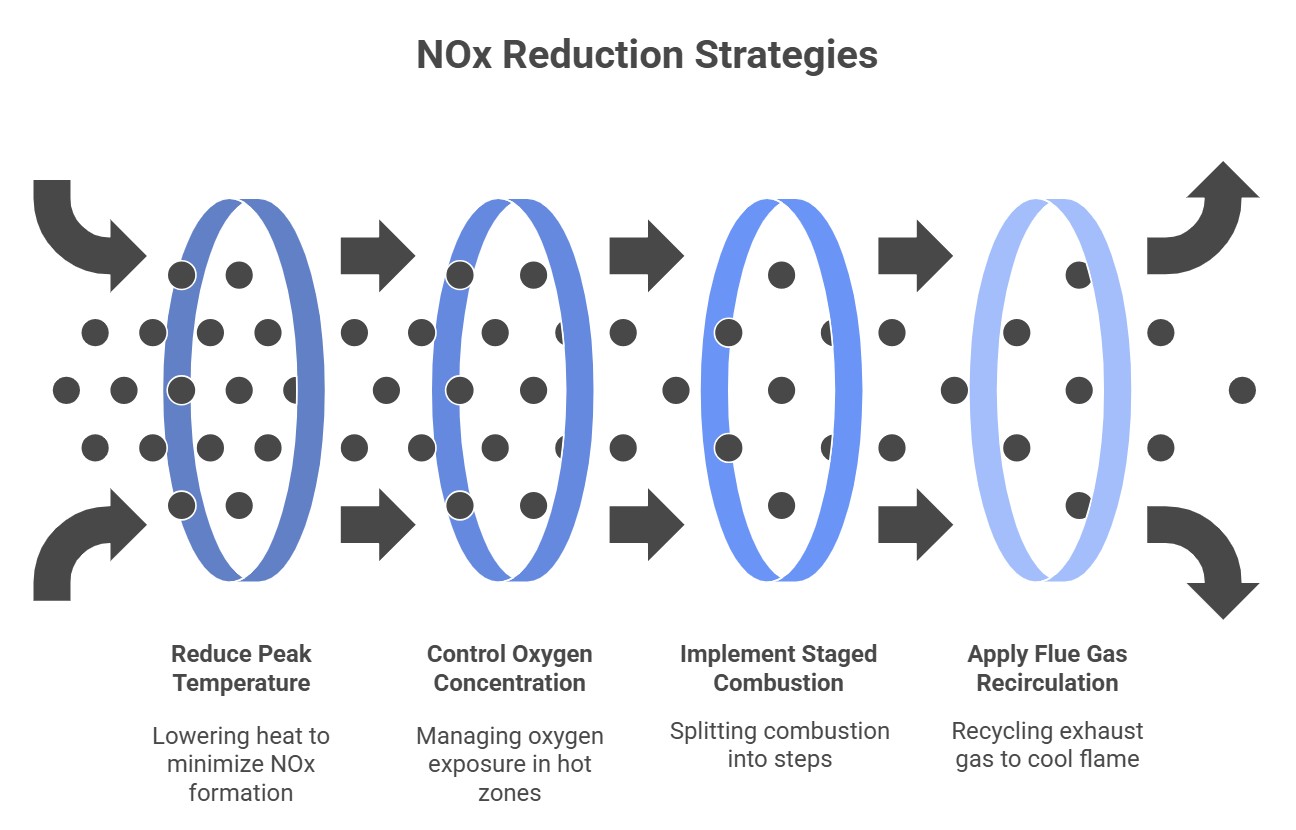

Low NOx burners focus on how combustion happens, not cleanup later. They manage heat release and oxygen placement inside the flame. We change mixing speed, flame shape, and reaction timing. That keeps NOx from forming in the first place. Think of it as guided combustion. Fuel and air meet step by step, not all at once. The flame stays stable, but less aggressive.

Thermal NOx rises fast at very high temperatures. So low NOx designs avoid sharp temperature peaks. They spread heat over a wider flame zone.

Ways this usually happens:

Slower fuel–air mixing

Larger flame volume

Heat dilution inside the reaction zone

Oxygen feeds NOx chemistry in hot zones. Low NOx burners control where oxygen goes. They delay some air until later in the flame. Early combustion runs fuel-rich. Later air finishes the burn downstream. This limits oxygen exposure at peak heat. It’s about where oxygen meets heat, not just how much.

Staged combustion splits the burn into steps. It’s one of the most common low NOx methods.

Air staging:

Less air at ignition

More air added later

Fuel staging:

Part of fuel burns first

Remaining fuel burns after mixing improves

Both reduce peak temperature and oxygen overlap.

| Staging type | What is staged | Main benefit |

|---|---|---|

| Air staging | Combustion air | Lower oxygen in hot zone |

| Fuel staging | Fuel flow | Slower heat release |

FGR sends some exhaust gas back to the burner. That gas carries heat but no oxygen. It cools the flame and dilutes oxygen.

Two common approaches exist:

Internal FGR using burner geometry

External FGR using ducts and fans

Both lower flame temperature effectively. Space and retrofit limits often decide which one fits.

Lower temperature can raise CO levels. CO rises when combustion becomes incomplete. This risk shows up at low loads or poor tuning. Good low NOx designs balance both sides. They reduce NOx without choking the flame. Controls, sensors, and tuning matter here. That balance keeps plants compliant and reliable.

Industrial boilers face strict emission permits. They run daily, often near populated areas. Low NOx burners help keep operations compliant. They appear in steam and hot water systems. Food plants, chemicals, paper mills rely on them. They also suit retrofit projects on existing boilers. Operators like predictable NOx across load changes. Stable flames matter during startup and shutdown.

High-temperature processes create higher NOx risk. Furnaces and kilns often run intense flames.

Low NOx burners reduce peak heat stress. You’ll find them in cement, steel, glass, ceramics. Heat must stay uniform across large chambers. Burner design affects product quality and yield. They often pair with staged combustion. Some sites add secondary NOx controls later.

Refineries use burners in many process heaters. They also power utility boilers across sites. Downtime carries high financial risk here. Low NOx burners offer reliability plus compliance. They handle variable fuels and long run times. Emission margins protect against audits and fines. Safety systems play a bigger role here. Designs often favor proven, robust solutions.

No two applications behave the same. Design starts with how heat is used.

Key factors engineers look at:

Fuel type and fuel nitrogen content

Cold air or preheated air supply

Direct-fired or indirect-fired heating

Required turndown and load cycling

These conditions shape burner choice and tuning. What works in a boiler may fail in a kiln.

A low NOx burner reduces emissions by controlling combustion itself. It reshapes fuel-air mixing, temperature peaks, and oxygen zones. This approach limits NOx formation at the source. Effective NOx reduction starts inside the flame. Combustion control works better than after-treatment alone. Choosing low or ultra low NOx depends on limits and operation needs.

If you’re sourcing a low-NOx burner, start at EBICO’s low-NOx burner overview. EBICO has built industrial burners since 1965. Share your fuel, firing rate, air temperature, and NOx limit, and we'll recommend a configuration. Contact our engineering team today.

Q: What is the main difference between a low NOx burner and an ultra low NOx burner?

A: The difference is emission limits. Ultra low NOx burners achieve lower NOx levels using more advanced combustion control or added technologies.

Q: When is a low NOx burner “good enough,” and when is ultra low NOx required?

A: Low NOx works where standard permits apply. Ultra low NOx is required in stricter regions or sensitive air-quality zones.

Q: What NOx level qualifies as “low NOx” for industrial burners?

A: It depends on local rules, often defined in mg/m³ or ppm, measured during certified stack testing.

Q: Can low NOx burners work with multiple fuels?

A: Yes, but fuel switching needs burner tuning, control adjustments, and sometimes hardware changes.

Q: How does turndown ratio affect NOx and flame stability?

A: Wider turndown makes stable low-NOx combustion harder, requiring careful burner and control design.