| Availability: | |

|---|---|

| Quantity: | |

Product Description

By adopting the revolutionary planar combustion ultra-low nitrogen tube bundle water-cooled furnace body technology, the planar combustion is composed of tens of thousands of micro-flames. Combined with the unique tube bundle type furnace body structure of the boiler, the flames are cooled rapidly, which greatly inhibits the generation of nitrogen oxides (NOx), and the nitrogen oxides (NOx) emissions are reduced to less than 15mg/m3.

The tubular furnace structure has a high heat transfer coefficient, requires less water storage, and can produce hot water within 5 minutes after startup. During the blowdown process, the heat loss is reduced by 20%, there is no preheating load loss, and the operating efficiency reaches as high as 104%.

It has truly achieved ultra-low nitrogen emissions, low noise levels, and high efficiency operation.

Product Advantage

Ultra-low nitrogen premixed flat burner: Ultra-low nitrogen premixed flat combustion technology

U-shaped stainless steel 304 heat exchanger:

High heat transfer coefficient, high pressure resistance, capable of natural expansion and contraction, detachable, easy to maintain, long service life

Heat transfer reaction water pipe:

Enhance the heat exchange efficiency. The preheating process only takes 5 minutes, with no loss of preheating load. The combustion takes place in the water pipes, with a low combustion temperature, which significantly controls the production of nitrogen oxides.

Stainless steel 304 condenser:

Absorb latent heat, reduce smoke density, enhance boiler thermal efficiency, and be corrosion-resistant.

Self-priming safety valve:

Achieve 100% safety, automatic pressure relief, and negative pressure adsorption

Intelligent Control:

Intelligent touch screen displays Chinese text for working conditions, offers remote control, and has an online operation guide.

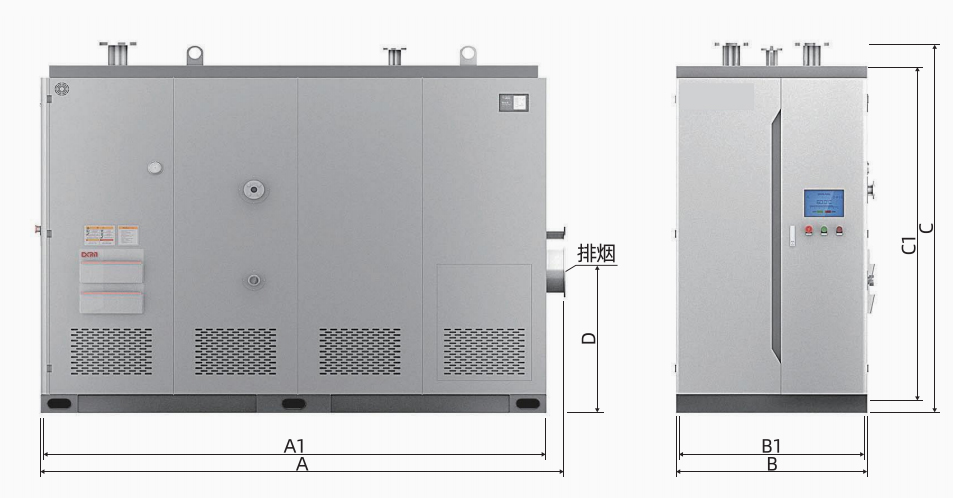

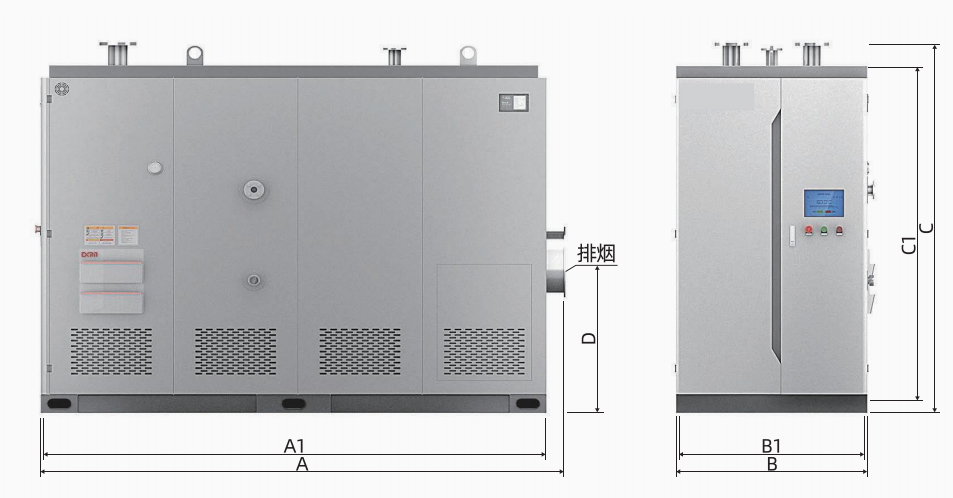

External Dimensions

Thermal efficiency 94%

| Model Number | A(Length) | B(Width) | C(Height) | D | A1 | B1 | C1 |

| Ultra0.35-V | 2300 | 800 | 1700 | 480 | 2100 | 800 | 1500 |

| Ultra0.47-V | 2300 | 850 | 1700 | 480 | 2100 | 850 | 1600 |

| Ultra0.58-V | 2500 | 850 | 1800 | 525 | 2300 | 850 | 1600 |

| Ultra0.7-V | 2500 | 850 | 1800 | 525 | 2300 | 850 | 1600 |

| Ultra0.93-V | 2700 | 1100 | 2000 | 650 | 2500 | 1100 | 1800 |

| Ultra1.05-V | 2800 | 1100 | 2000 | 700 | 2600 | 1100 | 1800 |

| Ultra1.16-V | 2800 | 1100 | 2000 | 740 | 2600 | 1100 | 1800 |

| Ultra1.4-V | 3000 | 1250 | 2300 | 810 | 2800 | 1250 | 2050 |

| Ultra1.75-V | 3200 | 1250 | 2400 | 865 | 3000 | 1250 | 2100 |

| Ultra2.1-V | 3400 | 1300 | 2550 | 920 | 3200 | 1300 | 2300 |

| Ultra2.32-V | 3400 | 1400 | 2600 | 960 | 3200 | 1400 | 2350 |

| Ultra2.8-V | 3800 | 1600 | 2600 | 985 | 3600 | 1600 | 2350 |

| Ultra3.5-V | 3800 | 1800 | 2750 | 1076 | 3600 | 1800 | 2500 |

| Ultra4.2-V | 4000 | 2000 | 2750 | 1076 | 3800 | 2000 | 2500 |

| Ultra4.9-V | 4850 | 2200 | 3050 | 1076 | 4650 | 2200 | 2750 |

| Ultra5.6-V | 4850 | 2400 | 3250 | 1100 | 4650 | 2400 | 3000 |

| Ultra7.0-V | 4850 | 2600 | 3250 | 1200 | 4650 | 2600 | 3000 |

| Ultra10.5-V | 5600 | 2800 | 3400 | 1200 | 5400 | 2800 | 3200 |

Thermal efficiency 96-104%

| Model Number | A(Length) | B(Width) | C(Height) | D | A1 | B1 | C1 |

| Ultra0.35-VL | 2500 | 800 | 1700 | 480 | 2300 | 800 | 1500 |

| Ultra0.47-VL | 2500 | 850 | 1700 | 480 | 2600 | 850 | 1600 |

| Ultra0.58-VL | 2800 | 850 | 1800 | 525 | 2600 | 850 | 1600 |

| Ultra0.7-VL | 2800 | 850 | 1800 | 525 | 2600 | 850 | 1600 |

| Ultra0.93-VL | 3300 | 1100 | 2000 | 650 | 3100 | 1100 | 1800 |

| Ultra1.05-VL | 3400 | 1100 | 2000 | 700 | 3200 | 1100 | 1800 |

| Ultra1.16-VL | 3400 | 1100 | 2000 | 740 | 3200 | 1100 | 1800 |

| Ultra1.4-VL | 3600 | 1250 | 2300 | 810 | 3400 | 1250 | 2050 |

| Ultra1.75-VL | 3850 | 1250 | 2400 | 865 | 3650 | 1250 | 2150 |

| Ultra2.1-VL | 3850 | 1300 | 2550 | 920 | 3650 | 1300 | 2300 |

| Ultra2.32-VL | 3850 | 1400 | 2600 | 960 | 3650 | 1400 | 2350 |

| Ultra2.8-VL | 4000 | 1600 | 2600 | 985 | 3800 | 1600 | 2350 |

| Ultra3.5-VL | 4250 | 1800 | 2750 | 1076 | 4050 | 1800 | 2500 |

| Ultra4.2-VL | 4400 | 2000 | 2750 | 1076 | 4200 | 2000 | 2500 |

| Ultra4.9-VL | 5200 | 2200 | 3050 | 1076 | 5000 | 2200 | 2750 |

| Ultra5.6-VL | 5400 | 2400 | 3250 | 1100 | 5200 | 2400 | 3000 |

| Ultra7.0-VL | 5400 | 2600 | 3250 | 1200 | 5200 | 2600 | 3000 |

| Ultra10.5-VL | 6000 | 2800 | 3400 | 1200 | 5800 | 2800 | 3200 |

Performance Parameter Table

model | Ultra-V | |||||||||||||||||||

Rated heating capacity | 104Kcal/h | 30 | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 480 | 600 | 900 | |

KW | 350 | 470 | 582 | 700 | 930 | 1050 | 1163 | 1400 | 1750 | 2100 | 2326 | 2800 | 3500 | 4200 | 4900 | 5600 | 7000 | 10500 | ||

power supply | - | 380V/50Hz | ||||||||||||||||||

Power distribution | KW | 1.5 | 1.5 | 2.2 | 2.2 | 4 | 4 | 5.5 | 7.5 | 7.5 | 11 | 11 | 15 | 15 | 18 | 22 | 22 | 30 | 45 | |

natural gas | Thermal efficiency 94% energy consumption | Nm3/h | 37.1 | 49.4 | 61.8 | 74.2 | 98.9 | 111.3 | 123.7 | 148.4 | 185.5 | 222.6 | 247.4 | 296.8 | 371.1 | 445.3 | 519.5 | 593.7 | 758 | 1129.1 |

Medium-pressure natural gas | Gas supply port diameter | DN | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 65 | 65 | 65 | 80 | 80 | 80 | 100 |

Gas supply pressure | kpa | 4-5 | 5-8 | 5-8 | 6-8 | 6-8 | 6-8 | 10-15 | 10-15 | 10-15 | 15-20 | 15-20 | 15-20 | 15-20 | 20-25 | 20-25 | 20-25 | 20-25 | 20-25 | |

Combustion regulation method | - | Electronic proportional control | ||||||||||||||||||

Thermal efficiency 94% | Heat transfer fluid capacity | kg | 270 | 400 | 450 | 500 | 510 | 530 | 540 | 772 | 890 | 910 | 930 | 1025 | 1225 | 1395 | 1550 | 1850 | 2460 | 3700 |

Boiler net weight | kg | 1000 | 1039 | 1139 | 1229 | 2200 | 2142 | 2136 | 2700 | 3320 | 3672 | 3800 | 5100 | 5892 | 6800 | 7180 | 8200 | 9500 | 10800 | |

Running weight | kg | 1270 | 1439 | 1589 | 1729 | 2710 | 2672 | 2676 | 3472 | 4210 | 4582 | 4730 | 6125 | 7117 | 8195 | 8730 | 10050 | 11960 | 14500 | |

flue diameter | DN | 200 | 200 | 250 | 250 | 300 | 300 | 300 | 350 | 400 | 450 | 450 | 500 | 550 | 600 | 650 | 650 | 700 | 800 | |

Type A heat exchanger | Δt=10℃ | Suitable for inlet/outlet temperatures of 45℃/55℃, applicable to underfloor heating and central air conditioning heating circulation. | ||||||||||||||||||

Rated heating capacity | 104Kcal/h | 30 | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 480 | 600 | 900 | |

Hot water flow | m3/h | 30 | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 480 | 600 | 900 | |

Pressure loss | mH2O | 1.08 | 1.12 | 1.56 | 1.02 | 1.61 | 1.21 | 1.24 | 1.58 | 1.76 | 2.47 | 2.75 | 3.84 | 6.15 | 5.82 | 3.8 | 4.0 | 5.0 | 5.4 | |

Pipe caliber | DN(mm) | 65 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 125 | 150 | 150 | 150 | 200 | 250 | 250 | 350 | 350 | |

Type B heat exchanger | Δt=20℃ | Suitable for inlet/outlet temperatures of 40℃-60℃, applicable to domestic hot water circulation. | ||||||||||||||||||

Rated heating capacity | 104Kcal/h | 30 | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 480 | 600 | 900 | |

Hot water flow | m3/h | 15 | 20 | 25 | 30 | 40 | 45 | 50 | 60 | 75 | 90 | 100 | 120 | 150 | 180 | 210 | 240 | 300 | 450 | |

Pressure loss | mH2O | 0.28 | 0.3 | 0.41 | 0.27 | 0.43 | 0.3 | 0.33 | 0.42 | 0.71 | 0.67 | 0.73 | 1.02 | 1.64 | 1.60 | 5.5 | 6.5 | 7.0 | 7.1 | |

Pipe caliber | DN(mm) | 65 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 125 | 150 | 150 | 150 | 200 | 200 | 200 | 200 | 200 | |

C-type heat exchanger | Δt=40℃ | Suitable for inlet/outlet temperatures of 35℃, 75℃, or 45/85℃, applicable to radiator heating circulation. | ||||||||||||||||||

Rated heating capacity | 104Kcal/h | 30 | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 480 | 600 | 900 | |

Hot water flow | m3/h | 7.5 | 10 | 12.5 | 15 | 20 | 22.5 | 25 | 30 | 37.5 | 45 | 50 | 60 | 75 | 90 | 104 | 120 | 140 | 225 | |

Pressure loss | mH2O | 0.61 | 0.97 | 0.69 | 0.95 | 0.85 | 0.95 | 1.02 | 1.00 | 1.09 | 1.73 | 1.79 | 2.07 | 3.40 | 5.22 | 2.3 | 3.3 | 3.5 | 3.6 | |

Pipe caliber | DN(mm) | 32 | 65 | 65 | 65 | 65 | 65 | 65 | 80 | 100 | 100 | 100 | 125 | 125 | 125 | 200 | 200 | 200 | 200 | |

The standard supply pressure of the heat exchanger is 1.0 MPa. For pressures of 1.6 MPa and 2.0 MPa, please specify.

The standard supply of the heat exchanger is a single-loop system; multi-loop systems are optional.

The temperature difference of the heat exchanger can be customized according to customer requirements.

The standard supply material of the heat exchanger is 304 stainless steel. Other materials can be customized according to customer requirements. For boilers with a thermal efficiency of 92%, please consult the company regarding the heat transfer fluid volume, boiler net weight, and dimensions.

The boiler energy adjustment range is 20%~100%. The lower heating value of natural gas is 8600 kcal/Nm³, and the lower heating value of liquefied petroleum gas is 22300 kcal/Nm³. The gas pressures in the table are flow pressures. For other fuel flow pressures and pipe diameters, please contact the company. It is recommended that the natural gas connection pipe diameter be one size larger than that shown in the table. The above performance tables are subject to change without notice due to technical improvements.

model | Ultra-VL | |||||||||||||||||||

Rated calorific value | 104Kcal/h | 30 | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 480 | 600 | 900 | |

KW | 350 | 470 | 582 | 700 | 930 | 1050 | 1163 | 1400 | 1750 | 2100 | 2326 | 2800 | 3500 | 4200 | 4900 | 5600 | 7000 | 10500 | ||

power supply | - | 380V/50Hz | ||||||||||||||||||

Power distribution | KW | 1.5 | 1.5 | 2.2 | 2.2 | 4 | 4 | 5.5 | 75 | 75 | 11 | 11 | 15 | 15 | 18 | 22 | 22 | 30 | 45 | |

Thermal efficiency | % | 96% 98% 104% | ||||||||||||||||||

natural gas | 96% thermal efficiency and energy consumption | Nm3/h | 36.3 | 48.4 | 60.6 | 72.7 | 96.9 | 109.0 | 121.1 | 145.3 | 181.7 | 218.0 | 242.2 | 290.7 | 363.4 | 436.0 | 508.7 | 581.4 | 726.7 | 1090.1 |

98% thermal efficiency and energy consumption | Nm3/h | 35.6 | 47.5 | 59.3 | 71.2 | 94.9 | 106.8 | 118.7 | 142.4 | 178.0 | 213.6 | 237.3 | 284.8 | 356.0 | 427.1 | 498.3 | 569.5 | 711.9 | 1067.9 | |

Thermal efficiency 104% energy consumption | Nm3/h | 33.5 | 44.7 | 55.9 | 67.1 | 89.4 | 100.6 | 111.8 | 134.2 | 167.7 | 201.3 | 223.6 | 268.3 | 335.4 | 402.5 | 469.6 | 536.7 | 670.8 | 1006.3 | |

Medium-pressure natural gas | Gas supply port diameter | DN | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 65 | 65 | 65 | 80 | 80 | 80 | 100 | |

Gas supply pressure | KPa | 4-5 | 5-8 | 5-8 | 6-8 | 6-8 | 6-8 | 10-15 | 10-15 | 10-15 | 15-20 | 15-20 | 15-20 | 15-20 | 20-25 | 20-25 | 20-25 | 20-25 | ||

Combustion regulation method | - | Electronic proportional control | ||||||||||||||||||

Heat transfer water container | Kg | 270 | 400 | 450 | 500 | 510 | 530 | 540 | 772 | 890 | 910 | 930 | 1025 | 1225 | 1395 | 1550 | 1850 | 2460 | 3700 | |

Boiler net weight | Kg | 1350 | 1400 | 1450 | 1520 | 2400 | 2450 | 2510 | 2950 | 3560 | 4050 | 4350 | 5500 | 6580 | 7200 | 7650 | 8700 | 10600 | 11800 | |

Total number of operations | Kg | 1620 | 1800 | 1900 | 2020 | 2910 | 2980 | 3050 | 3722 | 4450 | 4960 | 5280 | 6525 | 7805 | 8595 | 9200 | 10550 | 13060 | 15500 | |

flue diameter | DN | 200 | 200 | 250 | 250 | 300 | 300 | 300 | 350 | 400 | 450 | 450 | 500 | 550 | 600 | 650 | 650 | 700 | 800 | |

Type A heat exchanger | Δt=10℃ | Inlet/outlet temperature 45℃/55℃. Suitable for underfloor heating and central air conditioning heating circulation. | ||||||||||||||||||

Rated heating capacity | 104Kcal/h | 30 | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 480 | 600 | 900 | |

Hot water flow | m3/h | 30 | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 480 | 600 | 900 | |

Pressure loss | mH2O | 1.08 | 1.12 | 1.56 | 1.02 | 1.61 | 1.21 | 1.24 | 1.58 | 1.76 | 2.47 | 2.75 | 3.84 | 6.15 | 5.82 | 3.8 | 4.0 | 5.0 | 5.4 | |

Pipe caliber | DN(mm) | 65 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 125 | 150 | 150 | 150 | 200 | 250 | 250 | 350 | 350 | |

Type B heat exchanger | Δt=20℃ | Inlet/outlet temperatures of 40℃/60℃ are suitable for domestic hot water circulation. | ||||||||||||||||||

Rated heating capacity | 104Kcal/h | 30 | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 480 | 600 | 900 | |

Hot water flow | m3/h | 15 | 20 | 25 | 30 | 40 | 45 | 50 | 60 | 75 | 90 | 100 | 120 | 150 | 180 | 210 | 240 | 300 | 450 | |

Pressure loss | mH2O | 0.28 | 0.30 | 0.41 | 0.27 | 0.43 | 0.3 | 0.33 | 0.42 | 0.71 | 0.67 | 0.73 | 1.02 | 1.64 | 1.60 | 5.5 | 6.5 | 7.0 | 71 | |

Pipe caliber | DN(mm) | 65 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 125 | 150 | 150 | 150 | 200 | 200 | 200 | 200 | 200 | |

C-type heat exchanger | Δt=40℃ | Inlet/outlet temperatures of 35℃/75℃ or 45/85℃ are suitable for radiator heating circulation. | ||||||||||||||||||

Rated heating capacity | 104Kcal/h | 30 | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 150 | 180 | 200 | 240 | 300 | 360 | 420 | 480 | 600 | 900 | |

Hot water flow | m3/h | 7.5 | 10 | 12.5 | 15 | 20 | 22.5 | 25 | 30 | 37.5 | 45 | 50 | 60 | 75 | 90 | 104 | 120 | 140 | 225 | |

Pressure loss | mH2O | 0.61 | 0.97 | 0.69 | 0.95 | 0.85 | 0.95 | 1.02 | 1.00 | 1.09 | 1.73 | 1.79 | 2.07 | 3.40 | 5.22 | 2.3 | 3.3 | 3.5 | 3.6 | |

Pipe caliber | DN(mm) | 32 | 65 | 65 | 65 | 65 | 65 | 65 | 80 | 100 | 100 | 100 | 125 | 125 | 125 | 200 | 200 | 200 | 200 | |

The standard supply pressure of the heat exchanger is 1.0 MPa. For pressures of 1.6 MPa and 2.0 MPa, please specify.

The standard supply of the heat exchanger is a single-loop system; multi-loop systems are optional.

The temperature difference of the heat exchanger can be customized according to customer requirements.

The standard supply material of the heat exchanger is 304 stainless steel; other materials can be customized according to customer requirements.

For boilers with thermal efficiencies of 96% and 98%, please consult our company regarding the heat transfer fluid volume, boiler net weight, and dimensions.

The boiler energy adjustment range is 20%~100%.

The lower heating value of natural gas is 8600 kcal/Nm³, and the lower heating value of liquefied petroleum gas is 22300 kcal/Nm³.

The gas pressures in the table are flow pressures; for other fuels, please contact our company for flow pressure and pipe diameter.

It is recommended that the natural gas connection pipe diameter be one size larger than that shown in the table.

The above performance tables are subject to change without notice due to technical improvements.

content is empty!

content is empty!