Views: 0 Author: Site Editor Publish Time: 2026-01-14 Origin: Site

Fuel costs are rising, and emissions rules are tightening in 2026. Many boiler burners look fine, yet quietly waste fuel and money. So should you replace or retrofit your boiler burner? That decision now affects efficiency, compliance, and operating risk. In this guide, you’ll learn how to evaluate a boiler burner upgrade or replacement, and what it really costs.

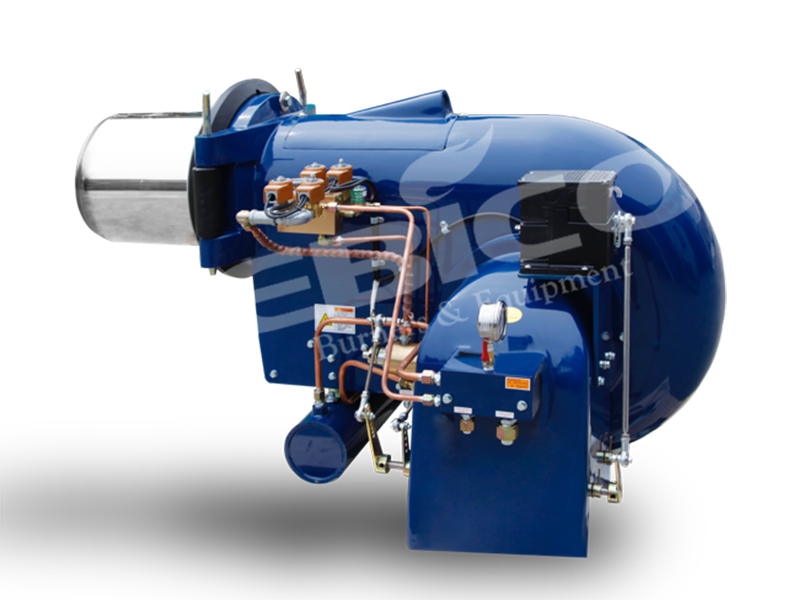

A boiler burner is the main heat source in an industrial boiler system. It converts fuel into controlled thermal energy, allowing the boiler to produce steam or hot water. As the primary heat-generating component, it delivers energy into the furnace in a stable, controlled way as load conditions change. In daily operation, the burner largely determines fuel efficiency, steam pressure stability, emissions such as NOx and CO, overall boiler safety, and long-term operating cost.

Common designs include gas burners for clean response, oil burners for strong heat output, dual-fuel burners for flexibility, and low or ultra-low NOx burners designed to meet strict emissions regulations.

| Boiler Burner Type | Typical Use | Key Characteristics |

|---|---|---|

| Gas boiler burners | Natural gas systems | Clean combustion, fast response |

| Oil boiler burners | Heavy or light oil | Strong flame, higher atomization needs |

| Dual-fuel boiler burners | Fuel-flexible plants | Switch between gas and oil |

| Low NOx boiler burners | Emissions-controlled sites | Reduced flame temperature and staged mixing |

| Ultra-low NOx burners | Strict regulations | Advanced mixing and combustion control |

Deciding whether to replace or upgrade a boiler burner is rarely a single-point decision. Most burners do not fail suddenly or dramatically. Instead, performance, efficiency, and compliance decline slowly over years of operation. That gradual decline often hides real costs and growing operational risk. A structured assessment helps reveal whether the burner still supports current and future needs.

Most industrial boiler burners are designed for long service life. On paper, many are rated for 20 to 30 years of operation. In real plants, usable life is often much shorter. Design life assumes stable loads, clean fuel, and ideal maintenance. Actual operation includes frequent startups, load swings, and aging controls. As components wear, combustion quality degrades even if the burner still “runs.” In many cases, efficiency losses appear years before mechanical failure. The burner works, but it no longer works well.

Performance changes are usually the earliest warning signals. They tend to appear gradually and are easy to overlook.

Common signs include:

A slow but steady increase in fuel consumption

Poor response during load changes

Flame instability at low or high firing rates

Steam conditions often reveal these problems first. Temperature or pressure may fluctuate more than expected. Operators compensate manually, but fuel use continues to rise.

Maintenance history provides strong evidence of burner condition. As burners age, reliability often declines before failure occurs.

Key indicators to watch include:

Increasing unplanned shutdowns or nuisance trips

Control components no longer supported by manufacturers

Longer repair times due to spare part shortages

Maintenance labor increases year by year. Downtime becomes harder to schedule and more expensive. Eventually, keeping the burner running consumes more resources than improving it.

Emissions requirements change faster than most burners age. Compliance issues often force the replacement decision.

Common red flags include:

NOx emissions approaching regulatory limits

Boiler output reduced to remain compliant

Little margin left for tighter future standards

Some plants rely on derating to pass inspections. That approach reduces capacity and increases risk. When future low NOx limits arrive, retrofit options may be limited or unavailable.

These questions help frame the decision early:

Can it operate reliably for the next 3–5 years?

Can emissions targets be met without major compromises?

Is it limiting boiler efficiency or usable output?

If several answers raise concern, the burner should be evaluated for retrofit or replacement planning, before cost and risk increase further.

Should we upgrade what we have, or start fresh? Both options improve performance, but they solve different problems. The right choice depends on condition, goals, and risk tolerance.

A boiler burner retrofit upgrades parts of an existing burner. The main structure stays in place. Key systems are improved to boost efficiency or compliance.

Common retrofit scopes include:

Control system upgrades

Older relay logic is replaced by modern digital controls.

They improve accuracy and repeatability.

Low NOx retrofit solutions

Combustion staging or air management is modified.

It helps lower flame temperature and NOx formation.

Fuel conversion projects

Oil systems may switch to gas.

Gas burners may gain dual-fuel capability.

Air-fuel ratio optimization

Fans, dampers, and controls are tuned together.

Combustion becomes cleaner and more stable.

Retrofits focus on improvement, not reinvention.

Boiler burner replacement removes the existing burner entirely. A new burner is installed in its place.

Replacement typically includes:

Full removal of the old burner assembly

Installation of a modern burner design

New combustion controls and safety systems

New burners are designed for today’s operating demands. They meet current emissions limits. They also allow room for future regulations and fuel strategies.

Retrofit works best under specific conditions. It assumes the burner still has a solid foundation. Retrofit is often suitable when:

The mechanical structure remains sound

Emissions exceed limits only slightly

Downtime windows are short

Capital budgets are tightly controlled

In these cases, upgrades deliver measurable gains. They improve efficiency and compliance without major disruption.

Replacement becomes necessary when limits are reached. Some problems cannot be fixed through upgrades alone.

Replacement is usually the better option when:

The burner design is outdated

Emissions targets cannot be met through retrofit

Higher turndown ratios are required

Fuel flexibility becomes critical

Digital monitoring and automation are needed

A new burner removes legacy constraints. It resets performance, compliance, and control capability.

| Decision Factor | Retrofit | Replacement |

|---|---|---|

| Initial cost | Lower | Higher |

| Downtime | Shorter | Longer |

| Emissions potential | Limited | High |

| Fuel flexibility | Moderate | Excellent |

| Control capability | Improved | Fully modern |

| Future-proofing | Partial | Strong |

Both paths deliver value. The difference lies in how far improvement must go.

Cost is often the deciding factor. Yet burner projects rarely fail because of equipment price alone. They fail when total cost is misunderstood. In 2026, energy prices and emissions rules make cost analysis even more critical.

A retrofit usually starts with targeted upgrades. The burner structure stays. Key systems receive improvements.

Typical retrofit cost elements include:

Combustion control upgrades

Digital controllers, sensors, and actuators improve accuracy.

They often deliver fast efficiency gains.

Low NOx modification costs

Air staging, internal recirculation, or burner inserts reduce NOx.

Costs vary based on reduction targets.

Engineering, commissioning, and tuning

Combustion tuning requires skilled specialists.

Time spent here affects final performance.

Retrofit costs vary widely by scope. Simple upgrades cost far less than deep emissions modifications.

Replacement involves a full system change. It includes more equipment and more labor.

Common replacement cost items include:

New burner equipment

Modern burners include advanced mixing and control features.

Installation and boiler interface modifications

Mounting, ducting, and fuel connections often need adjustment.

Commissioning, testing, and certification

New systems require full safety checks.

Emissions testing is often mandatory.

Replacement costs are higher upfront. They also deliver broader performance improvement.

Hidden costs often decide the real winner. They rarely appear in vendor quotations.

Common overlooked costs include:

Production downtime

Lost output can exceed equipment cost.

Compliance penalties or emissions risk

Operating close to limits carries financial exposure.

Long-term fuel inefficiency

Small efficiency losses add up over years.

Ignoring these costs skews decisions. They matter as much as purchase price.

Payback depends on fuel savings and risk reduction. Both retrofit and replacement can deliver returns.

Key ROI factors include:

Fuel savings comparison

New controls improve combustion accuracy.

New burners often deliver deeper savings.

Long-term cost of ownership

Replacement reduces maintenance and compliance risk.

Fuel price volatility

Higher fuel prices shorten payback periods.

In 2026, efficiency gains pay back faster. Energy cost pressure changes the math.

Choosing between replacement and retrofit is a strategic decision. It affects efficiency, compliance, risk, and future flexibility. The right answer depends on how the burner fits your operation today and tomorrow.

The first step is to look closely at the burner’s core technology. Some technical limits cannot be solved through tuning or minor upgrades. Older combustion designs often struggle to achieve stable, low NOx performance. Their flame shape, mixing method, and air staging options may already be pushed to the limit.

Control capability is just as important. Modern boilers operate across wide load ranges and frequent demand changes. They need precise air-fuel control and high turndown ratios to stay efficient. When controls lack accuracy, the burner cycles more often, wasting fuel and stressing components. If the technology itself restricts combustion quality or control precision, replacement becomes the more reliable path.

Technical capability must align with how the plant actually operates. What looks acceptable on paper may fail in daily production. In many cases, lost output costs more than the burner itself. Downtime tolerance plays a major role.

Retrofit projects usually fit into shorter shutdown windows. Full replacement often requires longer, carefully planned outages. The choice depends on how much interruption the process can absorb. Fuel strategy also matters. Some plants need dual-fuel capability for energy security or pricing flexibility. Others rely on a single, stable fuel source. If operational demands change, the burner must support them without adding risk.

Compliance is no longer a one-time target. Emissions standards continue to tighten across many regions. Decisions made today must hold up several years from now. Older burners may meet current NOx limits only by derating or narrow tuning. That leaves little margin for future regulations.

Retrofit solutions may help in the short term, but often have limited upgrade headroom. Sustainability goals add another layer of pressure. Efficiency and emissions increasingly affect reporting, audits, and public commitments. Newer burner designs support cleaner combustion and long-term ESG strategies. Planning ahead reduces regulatory risk and protects the plant’s reputation.

| Decision Factor | Retrofit | Replacement |

|---|---|---|

| Initial investment | Lower | Higher |

| Downtime | Shorter | Longer |

| Emissions potential | Moderate | High |

| Control precision | Improved | Excellent |

| Fuel flexibility | Limited | Broad |

| Long-term risk | Higher | Lower |

Each factor shifts the balance. The right choice matches technical limits, operational needs, and future goals.

Replacing a boiler burner involves more than choosing a new model. A poor match can limit performance, efficiency, and safety. Several technical and compliance factors must be checked early.

The burner must fit the boiler, not just in size, but in behavior. Heat input must match furnace volume and heat transfer surfaces. Too much input risks flame impingement. Too little reduces efficiency. Furnace geometry also matters. Flame length, diameter, and shape must suit the combustion chamber. The heat release profile should distribute energy evenly. Good matching protects tubes and improves heat absorption.

Emissions performance should be defined clearly. Verbal claims are not enough.

Key points to confirm include:

Guaranteed NOx levels

Targets should match operating load ranges.

Guarantees must reflect real fuel conditions.

Upgrade potential for future regulations

Designs should allow further NOx reduction.

Margin today reduces risk tomorrow.

A burner chosen only for current limits may age quickly.

Controls determine how the burner performs day to day. Modern systems rely on digital management.

Important features include:

PLC-based burner management

PLCs improve logic reliability and diagnostics.

They also simplify integration with plant systems.

Remote monitoring and diagnostics

Operators can track performance trends.

Early warnings help prevent unplanned shutdowns.

Better control improves efficiency, safety, and response speed.

Safety requirements cannot be treated as optional. They protect people, equipment, and production.

Critical areas include:

Fuel system safety

Valves, regulators, and interlocks must meet standards. Safe shutdown must be fast and reliable.

Compliance standards

Local and international codes may apply. Certification should match the installation region.

Meeting these requirements avoids delays, fines, and operational risk.

If you are evaluating a boiler burner upgrade or replacement, selecting the right manufacturer matters as much as the technology itself. EBICO is a proven choice for industrial boiler burner solutions.

EBICO specializes in high-efficiency, low-NOx boiler burners designed for demanding industrial applications.Our strengths include advanced combustion technology, precise control systems, and strong emissions performance. We also provides engineering support, customization, and global compliance expertise. For plants seeking reliable performance, future-ready emissions compliance, and long-term operational value, working with an experienced manufacturer like EBICO helps turn the burner decision into a strategic advantage.

Contact our boiler burner experts now.

A: Retrofit usually costs less upfront, but replacement may lower long-term fuel, maintenance, and compliance costs.

A: Most retrofits take days to weeks, depending on scope and shutdown windows.

A: Sometimes, but only for moderate targets. Very low NOx often requires replacement.

A: Modern burners often cut fuel use by 5–15% through better control and mixing.

A: Often yes, to ensure matching performance, emissions compliance, and control capability.